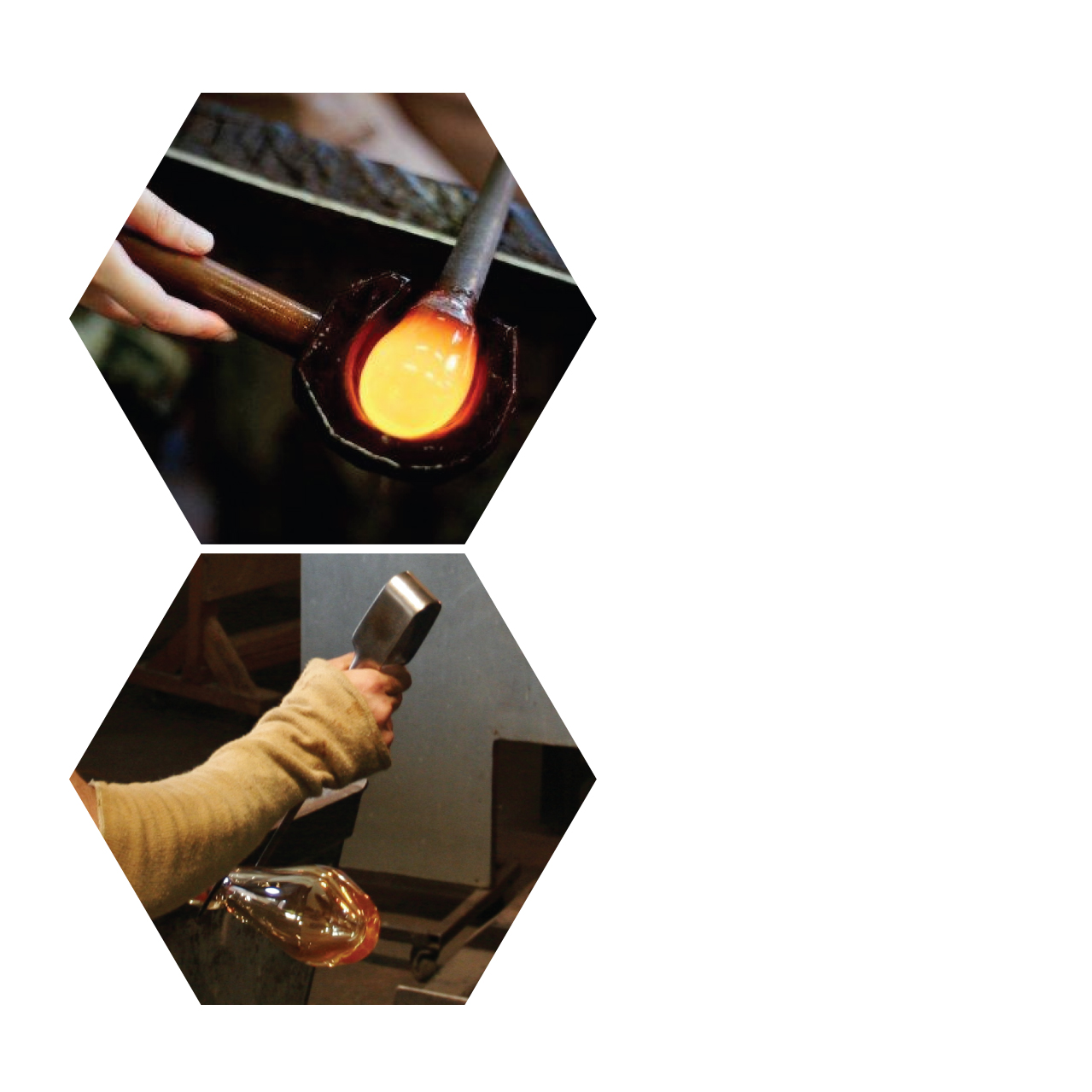

Forming Method Blowing

|

Glass Blowing involves three furnaces. The first furnace is where the unworked molten glass is stored. The glory hole is the second furnace, used to reheat the glass while it is being shaped. The third is the annealer, where the finished piece is left to cool. Molten glass from the first furnace is gathered on the tip of a preheated blowpipe. The glass is then shaped through a series of blowing, rolling it on a flat surface (or marver), and manipulating the form with various tools. |

|

|

Forming Methods Finishes Assembly Options |

| * click on the images to enlarge * |